- |<

- <

- 1

- >

- >|

-

(Interview with Professor Yousuke OOYAMA of Hiroshima University)Yousuke OOYAMA, Tatsuya SHIGEHIRO2025 Volume 98 Issue 7 Pages 176-178

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

JOURNAL FREE ACCESS近年,環境対応(脱炭素化,エネルギー問題)など地球規模で世の中が目まぐるしく変化しています。これらは経済のみならずわれわれの生活様式にまで多大な影響を与えています。同様に色材や界面制御に関する研究においても,この大きな社会変化への適応が求められています。そこで本誌では,小特集企画として「色材や界面制御に関する今後の動向」と題し,当分野において最先端で活躍される方々にインタビューを行い,今後の研究動向や社会動向などに関するお考えを不定期の連載形式で紹介しています。

今回はその第4回目として,色材の研究に関して幅広い経験・知識をお持ちである広島大学の大山陽介教授にインタビューを行いました。大山先生は有機化学などがご専門で,現在は有機色素の合成および物性評価,そして多岐に渡る応用検討など,新たな研究分野開拓を目指して色素の新機能を発掘することに日々,挑戦されております。

View full abstractDownload PDF (983K)

-

Mareki OHTSUJI, Kurumi HAYASHI2025 Volume 98 Issue 7 Pages 179-183

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

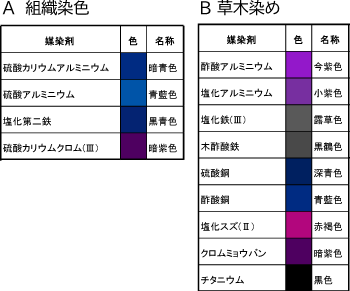

JOURNAL RESTRICTED ACCESSHematoxylin and eosin staining, a standard and essential method in pathology and histology, is widely used to visualize cell nuclei and cytoplasm. Hematoxylin, derived from the leguminous tree Haematoxylum campechianum, was discovered in Central America in the 16th century and used for microscopic staining in the 19th century. Tissue staining applications began in the 1860s and is still widely used clinically today. Hematoxylin is also applied to textile and leather dyeing, including Japan’s traditional “Kyo-kurozome” (Kyoto black dyeing). This review outlines the historical background and development of hematoxylin staining.

Fig. 6 Fullsize ImageView full abstractDownload PDF (3976K)

Fig. 6 Fullsize ImageView full abstractDownload PDF (3976K) -

Takahiro OKI, Ryusei AZUMA, Soichiro YAMANAKA2025 Volume 98 Issue 7 Pages 184-187

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

JOURNAL RESTRICTED ACCESSWe have developed LUSHADE® BLACK, a novel black pigment characterized by structure-induced light absorption. LUSHADE® BLACK enables the creation of low-gloss, deep jet-black coating films that are difficult to achieve with conventional pigments. While it strongly absorbs visible light, it selectively reflects near-infrared light. It is expected to be applied to stray light prevention materials for camera lenses and sensors, and LiDAR sensor materials.

View full abstractDownload PDF (2122K)

-

Kazuyuki MIYAZAWA, Yuji ITO2025 Volume 98 Issue 7 Pages 188-194

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

JOURNAL RESTRICTED ACCESSAdvancements in polymerization techniques have made it possible to easily synthesize precisely controlled polymers that were previously difficult to produce. In cosmetics, polymers serve various roles such as thickeners, film formers, dispersants, and sensory enhancers. To achieve higher functionality, it is essential to design and control their structures suitable for the purposes. We attempted to synthesize amphiphilic block copolymers using a simple and versatile method and investigated their adsorption behavior on inorganic surfaces using Quartz Crystal Microbalance with Dissipation monitoring (QCM-D). Additionally, we evaluated their effectiveness as surface treatment agents for inorganic particles. Our findings revealed that block copolymers adsorb more densely on surfaces compared to random copolymers, exhibit superior dispersibility in various oils, and help maintain lower viscosity in formulations by preventing particle aggregation.

View full abstractDownload PDF (2949K)

-

Naoki HAMADA2025 Volume 98 Issue 7 Pages 195-198

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

JOURNAL RESTRICTED ACCESSThe drying process is one of the finishing processes in organic pigment production, it is an important process that affects product quality and cost. In addition, it is a complicated process in which heat and water (solvent) move simultaneously, and shortening of drying time and energy saving are required. Therefore, it is necessary to optimize the equipment and process for each product.

In this paper, we first briefly touch on the matters to be considered when drying organic pigment, and then describe the characteristics of each dryer actually used in pigment production.

View full abstractDownload PDF (855K)

-

Yuji HIROSE, Haruka NAKAOKA2025 Volume 98 Issue 7 Pages 199-200

Published: July 20, 2025

Released on J-STAGE: July 20, 2025

JOURNAL FREE ACCESSDownload PDF (406K)

- |<

- <

- 1

- >

- >|