All issues

Predecessor

Volume 84, Issue 2

Displaying 1-6 of 6 articles from this issue

- |<

- <

- 1

- >

- >|

Original Research Paper

-

Daiki MINAMI, Satoshi HORIKOSHI, Kenichi SAKAI, Hideki SAKAI, Masahiko ...2010 Volume 84 Issue 2 Pages 39-42

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

JOURNAL FREE ACCESSThe adsorption behavior of surfactant molecules on the hydrophobic surface of single-wall carbon nanotubes (SWNTs) was examined experimentally by measurement of turbidity degree and average size of dispersed SWNTs aggregate, and the molecular dynamics (MD) techniques. Sodium dodecyl sulfate (SDS) and cetyltrimethylammonium bromide (CTAB) were used as model surfactants in aqueous media. The dispersion of SWNTs was investigated by MD simulation using the adsorption model of the surfactant on the SWNT surface. As a result, we found the clear difference of the adsorption behavior according to the kind of surfactants. The hydrophilic head group of SDS molecule adsorbed on the hydrophobic surface at the initial step of adsorption and the hydrophobic moiety of SDS repeated the adsorption and desorption on the surface. In contrast, the CTAB molecule formed the stable adsorption state on the hydrophobic surface. This adsorption behavior of surfactant molecule on the SWNTs surface affects the dispersion of SWNTs in aqueous media. Fig.3 Fullsize ImageView full abstractDownload PDF (2705K)

Fig.3 Fullsize ImageView full abstractDownload PDF (2705K) -

Nobuo AKAGI, Shigeyuki YAGI, Hiroyuki NAKAZUMI2010 Volume 84 Issue 2 Pages 43-46

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

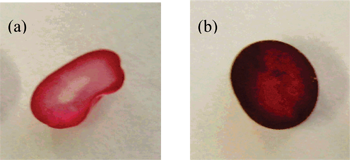

JOURNAL FREE ACCESSConventional polarized polypropylene (PP) films were prepared by uniaxial tensile drawing of the colored PP film dyed by the high-pressure dyeing process using azo dichroic dyes and prepared by heat-kneading-hot press method of PP resin and azo dichroic dyes.

Anisotropic behavior of the polarized PP films which oriented by additional uniaxial tensile drawing was evaluated by visible spectroscopy in polarized light. Dichroic ratios of azo dichroic dyes in PP film additionally stretched at drawing ratio of 5 are close to that in nematic liquid crystal and this polarized PP film shows a maximum polarizing efficiency of 92 % at λmax (531 nm) of azo dichroic dye.

These results show that an atactic PP has extensive amorphous region for dyeing of dichroic dyes and commercial dichroic dyes with azo chromophore are efficiently incorporated into the PP film by high-pressure dyeing process.

It is suggested that the heat-kneading processing of atactic PPs with dichroic dyes allows the preparation of better colored masterbatchs for the conventional polarized PP films. Fig.6 Fullsize ImageView full abstractDownload PDF (598K)

Fig.6 Fullsize ImageView full abstractDownload PDF (598K)

Review

-

Hiroshi SUZUKI2010 Volume 84 Issue 2 Pages 47-51

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

JOURNAL FREE ACCESSMany fluids used for color materials such as ink, paint and so on are classified as suspensions where small particles are suspended in liquid or air. Their viscosity characteristics are quite different to those of Newtonian fluids such as water or air. They are very complex and such fluids frequently exhibit visco-elasticity. Thus, it is very important to learn about visco-elastic fluids. Here, the fundamentals and principles of the rheology of visco-elastic fluids have been described. This manuscript will help to develop the color materials or applications.View full abstractDownload PDF (431K)

Review

-

Masakazu TAKAHASHI2010 Volume 84 Issue 2 Pages 52-56

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

JOURNAL FREE ACCESSOffset printing is used for various prints such as book, carton, leaflet, poster and newspaper.

The offset printing method, the ink formula, and its drying mechanism are explained in this review. In addition, the recent eco-friendly technology of the offset ink is introduced.View full abstractDownload PDF (2200K)

Serial Lecture

-

Hideki OKABE2010 Volume 84 Issue 2 Pages 57-63

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

JOURNAL FREE ACCESSThis review explains the features and conventional applications of each high performance pigments (HPP) classified by their chemical structure, and introduces the technical trend of HPP on their novel chemical structure and their application.View full abstractDownload PDF (1225K)

Serial Lecture

-

Kishio SHIBATO2010 Volume 84 Issue 2 Pages 64-72

Published: February 20, 2011

Released on J-STAGE: May 20, 2011

JOURNAL FREE ACCESSThe film forming processes by which coated wet paints are transformed to solid state are reviewed for coatings such as lacquers, ambient temperature curing coatings, waterborne coatings, powder coatings, thermoset coatings and UV coatings.

The chemical reactions taking place during curing are also reviewed.

Examples of curing progress measured by IR, DSC or titration are introduced, and examples of viscoelasticity change measured during the curing process are given.

The change of film appearance during curing is also discussed.View full abstractDownload PDF (880K)

- |<

- <

- 1

- >

- >|